| After a summer of thrashing

the original SPA3D, I decided to make my next one a little tougher.

Thanks to all the feedback and flight reports on the forums, this

is what I came up with. The "T" in SPA3DT stands for "Tubular" but

I also like "Tank" so take your pick! To build this airplane, you must

be very familure with the original

SPA3D

plans and Instructions. All I am presenting here is a photo

essay of what I did differently on this airplane, to give you more

ideas to work with. Fuselage length, wing measurements, tail measurements

and engine mount measurements are all identical to the original SPA3D.

The square aluminum fuselage material I used is much harder to work

with than the original SPA3D's "U" channel. It is also harder to

find and more expensive, but the result is a very clean, very tough

airplane with no flex and much better high speed performance. At the

same time, this airplane retains the original SPA3D's awesome slow

flight performance, and the all up flying weight is identical to the

original at 4 pounds 8 ounces. For power I'm using a beat up TT Pro .46

and a GP 10 ounce fuel tank. I've flown this airplane with several

different prop sizes and brands, and my favorite for this engine/airplane

combination is the APC 12 x 4. Hover is at slightly more than half

throttle, with plenty of power for vertical climb outs and all the

tricks you can think of! |

|

The fuselage material is

a 36" long x 1" square x 1/16" thick section of aluminum tubing.

I found it at TSC's for $9.50 for the 36" piece. Cool, it comes in

the exact length for the airplane! Some LOWES also carry it. Since

36" of the tubing is approximately 2 1/2 ounces heavier than the

original SPA3D's "U" channel fuselage, you will notice that I have

eliminated the Coroplast profile fuselage to save weight. For the

landing gear I used a 20" long x 1" wide x 1/8" thick piece of aircraft

grade T6 aluminum. It is shaped on a sheet metal roller where I work.

It is light, very springy and VERY tough!

|

|

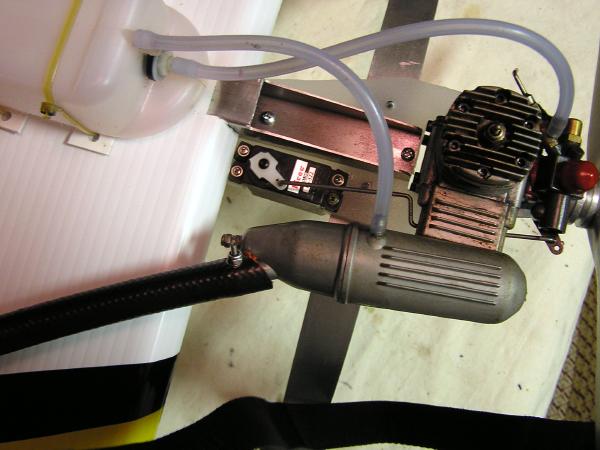

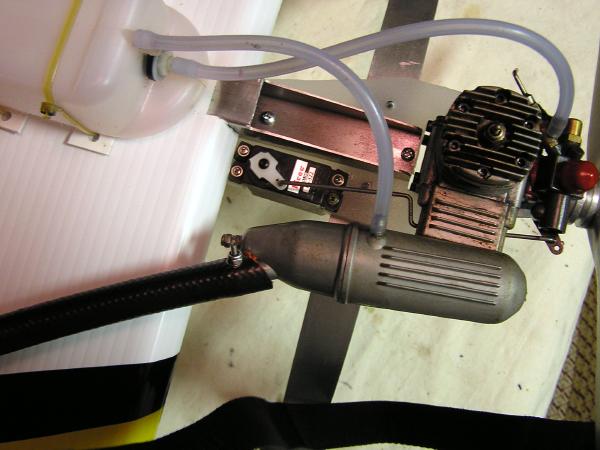

In the picture below you

will notice that I tapered the front of the aluminum tubing fuselage

for access to mount the engine mount, as well as shave off some weight.

This taper is 3" long, and goes to a wall height of 1/2" at the

front of the fuselage. I accomplished this using a hack saw, then

cleaning it up with a dremel stone, and finally removing the burrs

with a flat file. As with the original SPA3D, the fuselage is secured

to the engine mount with #6 x 3/4" self tapping screws into 1/16"

pilot holes. The landing gear and engine are also mounted to the

engine mount using these screws. I cannot stress enough that

the kitchen cutting board you use for the engine mount must say POLY

on the lable. The best brand (and the one I use exclusively!) is

"American Chef" and is available at Wal-Mart.

|

|

Another thing I did differently

from the original SPA3D is switch places between the throttle servo

and the landing gear mount location. Although I have never broken

a cutting board engine mount, I've read reports on the forums where

mounts had broken between the throttle servo cut-out and engine cut-out.

By switching these, there is much more "meat" behind the engine for

a tougher mount. You will also notice that I have shaved some dead

weight off of the corners of the engine mount, especially a very large

piece from the left rear. You may also notice the nice camera strap

hanging in the picture below.

|

|

The picture below shows the

rear fuselage taper to facilitate tail mounting and shave off some

more weight. This taper is 8" long and goes to a wall height of 1/2"

at the rear of the fuselage. You will also notice that I moved the

vertical stab/rudder 2" further forward than the original SPA3D.

The ONLY reason I did this was because I think it looks cooler. Another

very helpfull hint here is to add a few drops of CA glue to the tail

mount PVC doublers before screwing them down. This will keep the

Coroplast holes from elongating and pulling out from hard dirt doinkers.

|

|

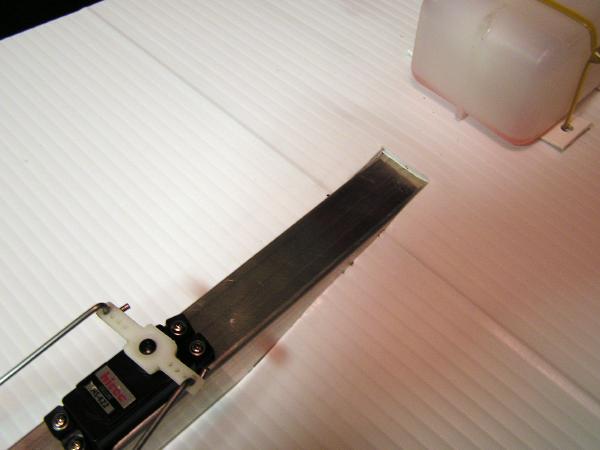

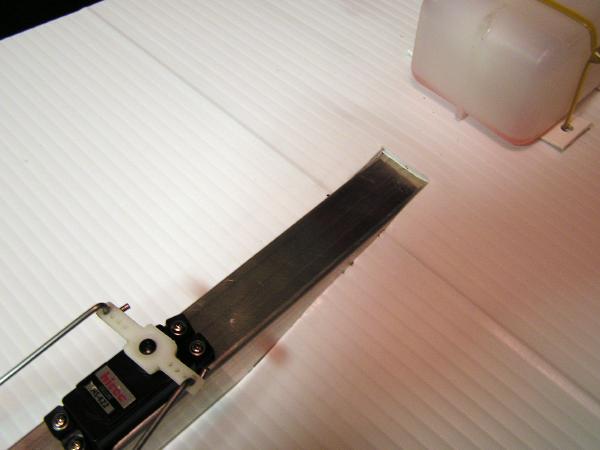

The picture below shows what

I believe is the single most important improvment to this airplane.

A poster named Coasty at

Spadworld

came up with this idea and it it brilliant! First of

all, the wing's fuselage cut-out needs to be enlarged to 1" wide

to accomidate the wider fuselage. Then note that the forward 18"

piece of 5/32" music wire spar no longer runs in the wing flute just

forward of the fuselage cut-out. It is now positioned 1" back from

the forward edge of the cut-out, and RUNS THROUGH the fuselage! To

accomplish this, I cut the wing out and positioned it on the airplane

and marked for the location of the hole. The hole is near the top

edge of the aluminum tubing. I then removed the wing and drilled

the 5/32" hole through the fuselage USING A DRILL PRESS to make

sure it was straight and square. When installing the wing on the

fuselage, I used a 1/8" piece of music wire as a "drift" to knock the

5/35" music wire spar in place, through the fuselage, centered in the

wing.

|

|

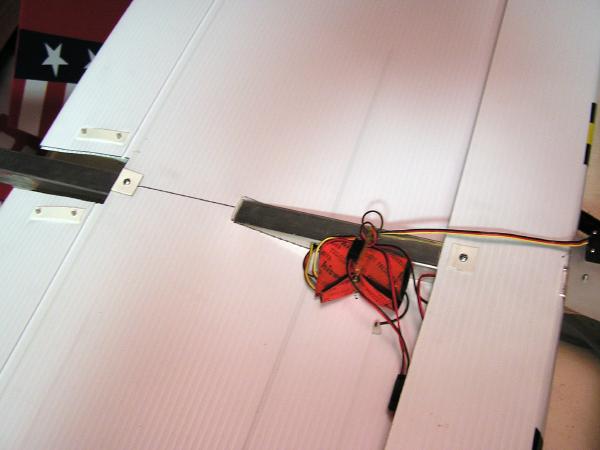

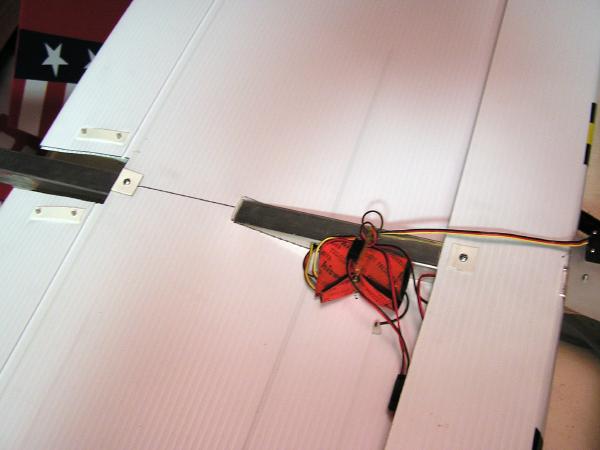

The picture below shows the

other two wing mount locations. One securing the wing trailing edge

and the other securing the forward lower wing. I used PVC doublers

and #6 x 1/2" self taping screws. I drilled the holes in the aluminum

slightly undersized, and self tapped the screws right into the aluminum.

They aren't going anywhere! Again, a couple drops of CA glue on the

doublers before tightening the screws down, will help prevent the

holes in the Coroplast from elongating on hard weed floppers. I would

also like to note that I increased the length of the rear 5/32" music

wire spar, that runs in the wing flute just in front of the ailerons,

to the full 36" wing span. You can see this clearly in some of the

overview pictures on this page. This gives the ailerons more support

and the wing less opposing flex. Make sure the rear 5/32" music wire

spar is in place before tightening down the rear wing mount screw.

I put the wing on it's side on the floor and pounded it in with a hammer.

|

|

The picture below shows the

hardest part of building this airplane. The servo cut-outs in the

aluminum fuselage. Once I determined where I wanted them, I used

the servos to mark the cut-out locations. I then drilled a hole in

the corner of each cut-out. I then used a Dremel cut-off wheel to

cut between the corner holes. Using a servo for test fitting, I cleaned

up the holes with a Dremel stone until the servos fit in the cut-outs.

I then took the burrs off with a flat file. Then, using a servo as

a template, I drilled for the servo screws using a 1/16" drill bit.

Then, using servo screws, and working gently in and out with a drop

of oil, I carefully tapped each hole. This was fun because I broke

several servo screws doing this, but was able to get the broken pieces

out of the hole with small vice grips. You will notice when you go

to put your servos in, that the bottom of the servo rests on the bottom

inside of the fuselage slightly before the servo ear grommets contact

the top of the fuselage. No problem, I tightened the servo screws

down anyways, and the grommets made contact with a little flex, and the

servos are nice and tight. I did check the servos screws between every

flight on the first afternoon of flying, and they didn't losen up

at all. You will also notice that there is juuuust enough room between

the servo and the inside side wall of the fuselage for the servo

wires to run. This also made for a headache trying to get the servos

in. I ended up scotch taping the wires to the inner side of the fuselage

while installing the servos, then pulling the tape out once the

servos were in place. Even though I don't drink, by this time I

was ready for a beer...so I had a Pepsi and a cigarette instead.

You will also notice in this picture that I increased the base length

of the aileron control horns to 2 1/4" for a bigger "footprint"

and less control surface flex.

|

|

The picture below goes with

the picture above, because you cannot install the servos until you

route the wires through the fuselage. You will notice that the wires

exit the fuselage through a hole just below the forward 5/32" music

wire spar. To make the hole, I drilled two 1/4" holes next to each

other and then connected them into an oval with a dremel stone. Make

sure you smooth and deburr this hole really well so that it doesn't

cut through your servo wires. To route the wires, I held the airplane

on it's nose as I put the servos in their cut-outs. I then used a

piece of coat hanger with a small hook bent on the end to grab the

wires and pull them out of the hole. You have to hold your glutes

just right, squint a little, roll your tounge and cuss a lot, but

you can get it. This picture also shows the battery installation with

double sided foam mounting tape, as well as the switch location I used.

The Rx is simply mounted with a zip-tie to the fuselage and the antenna

routes down a flute out to the wing tip.

|

|

The picture below proves

that the wing's leading edge doesn't have to be perfect. Also, since

the fuselage has a larger O.D. you will need to crease 8 flutes for

the leading edge instead of 5 flutes on the original SPA3D. Make

sure that the first of the folded flutes is still at 5" from the

top edge of the Coroplast, so this means that you will be adding

the three extra flutes to be folded, to the side closest to the

top edge of the Coroplast, on the SPA3D wing layout drawing. Also

the wing leading edge fuselage hole will need to be enlarged to 1"

wide x 8 flutes long. The wing tip coat hanger clips also need to be

enlarged to 1" wide.

|

|

You may have noticed while

viewing these pictures that I am using pushrods that have a Z-bend

at both ends. I simply make them slightly longer than needed, and

then put a "zig-zag" in the middle. To adjust them, I take the servo

arm off, and make the "zig-zag" sharper or shallower using pliers.

I started doing this about a year ago when Kraut crashed an airplane

because a clevis end stripped out. Not only that, but I can buy

a bunch of music wire and not have to worry about needing anything

else to rig my plane out with. I LOVE this method, it doesn't get

any simpler, and there is nothing to break or strip out. All the

pushrods on this airplane are made from 3/32" music wire. Making

the Z-bends is TOUGH, but well worth the effort. I have been scolded

several times for running such long single wire pushrods, but this is

usually by conventional builders with very little grasp of what we

do, and with no knowledge of how tough and stiff the music wire really

is! It is PLENTY stiff and strong enough to run the control surfaces

in any normal flight you could ever put this airplane through, while

at the same time, will bow slightly in a hard tail touch or dirt

nap cartwheel...so that your servo will survive and your plane will

fly on! Do this with a conventional wood-soft metal-clevis pushrods,

and you will break, bend, or strip out something, and it could be

the end of your flying afternoon. I rigged this airplane out just

like my original SPA3D with as much throw as I could get on all the

control surfaces. The CG range on this airplane is between 6" and

7" from the leading edge (set with an empty tank), depending on

how radical you want it to fly. I currently have mine set at 6 1/4"

and like it. I hope this photo essay has given you enough information

to give you some good ideas for building your next SPA3D type airplane,

and if you have further questions, please ask them at

Spadworld

or any of the other fine Spad forums listed on the

Spad home page

.

|

|

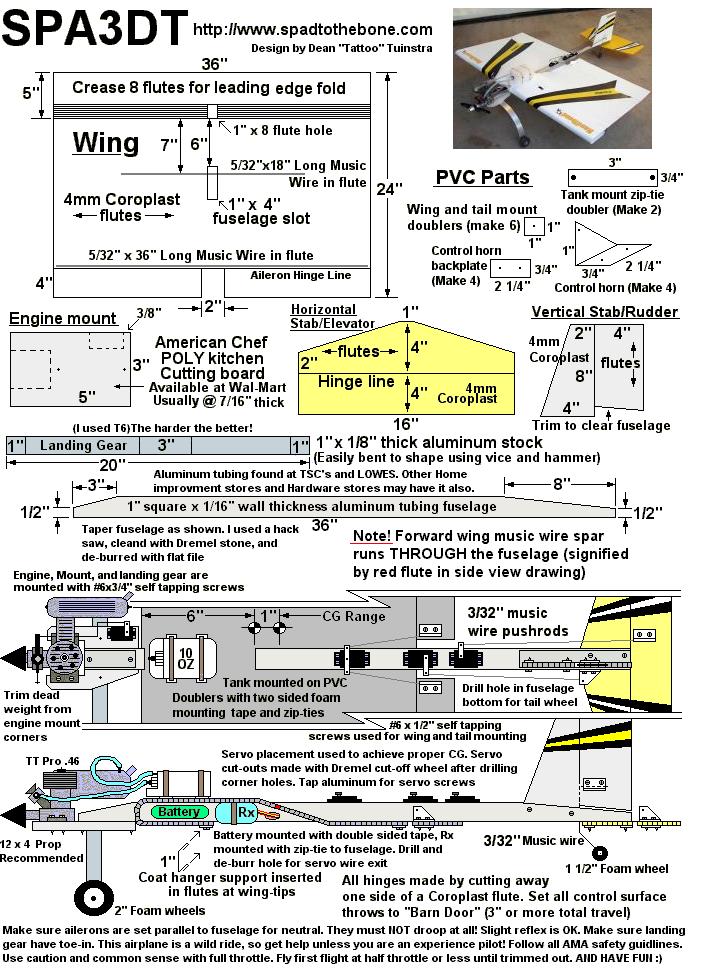

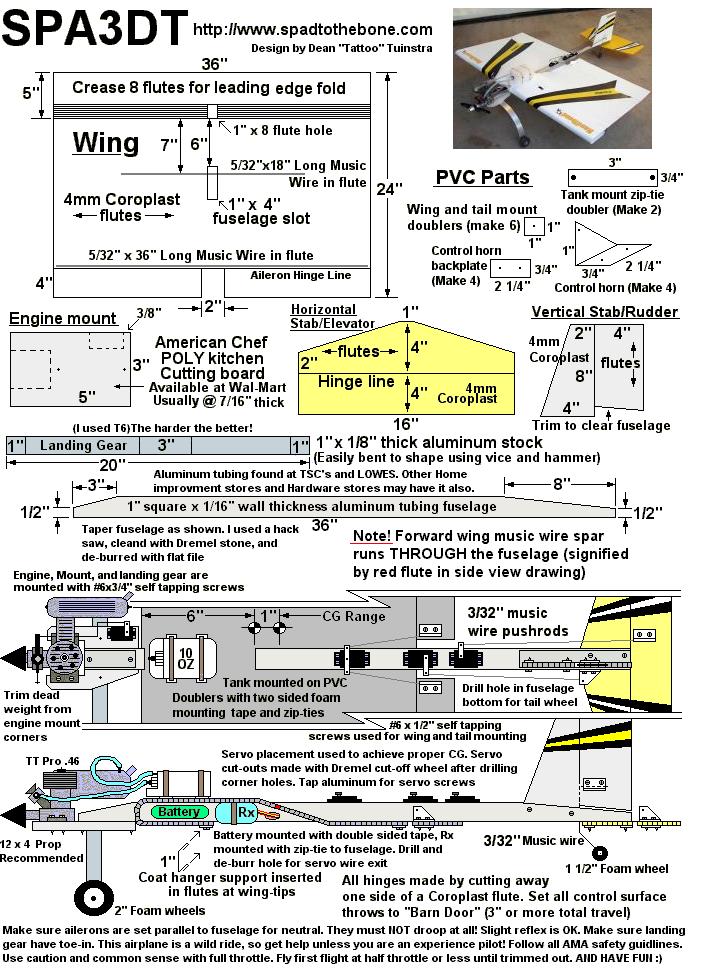

And last but not least,

below is the reference drawing for measurements. I added this drawing to

the page after doing the photo essay above, so it has all the necessary modifications

mentioned. I hope you have fun with this airplane, and don't get too mad

at me while you're making servo cut-outs and snaking your wires through the

fuselage :)

|

|

Back to the Spad Originals Index Page

|